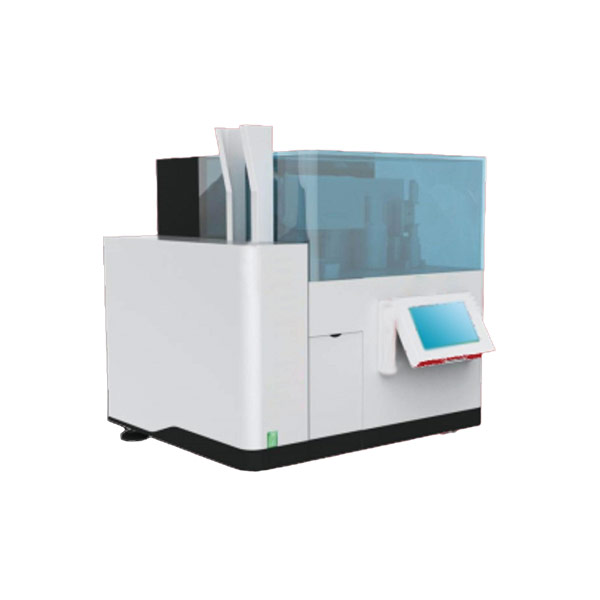

KH-F2

1.Large color touch screen,intuitive and generous,easy to operate;2.Color touch screen software shutdown;The loading door automatically opens and closes;

3.Guided machine operation mode -real-time dynamic guidance of operation process,anti misoperation processing mechanism;4.High sealing efficiency,fast speed,stable and reliable;

5.Arc motion envelope trajectory,uniform envelope,no bubbles,no overflow;6.Equipment fault self inspection function,timely locating the cause of faults,improving after-sales quality and efficiency;

7.Any combination or switching of single or double slide collection boxes;8.Broken cover fragments,intelligent detection of uncovered glass slides,3 suction attempts,and automatic alarm;

9.Intelligent detection of glass slide pick-up,3 grabs,automatic alarm;10.Automatic scanning function with two reciprocating cycles for detecting glass slide leakage;

11.Real time recording of the number of envelopes,the number of collection boxes for envelopes,automatic storage,and easy access at any time;12.Equipped with a quality control system,real-time storage of work content,long-term storage,and ready access;

13.Intelligent detection during the collection of glass slides,automatic card alarm,and automatic reset;14.Real time detection of the working position of the glue spraying needle,automatic alarm for deviation from the working position;

15.Real time recording of machine work results,permanent storage,convenient for quality control;16.Intelligent protection mode for the entire machine,with real-time fault prompt function; glass slide holders from various manufacturers and can be used in conjunction with dyeing machines from various manufacturers;

19.Can be upgraded to a dyeing and sealing workstation.